RAMSES Multi-Grid detector

Former MultiGrid prototypes developed in collaboration between France (ILL) and Sweden (ESS and Linkoping University) have shown their great potential to replace 3He-based detectors. However, one strong limitation of this technique comes from the mechanical constraints on the pressure vessel when the detector, filled with 1 bar, is operated in vacuum, as required for most of the Time-Of-Flight instruments. In order to sustain one bar differential pressure, the mechanical structure of the pressure vessel imposes important dead zones between the detection elements, resulting in degraded efficiency and uniformity.

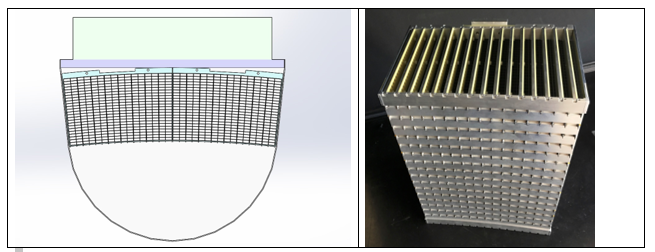

A new design of Multi-Grid detector, called the RAMSES design, as reference to the ILL instrument to which it is devoted, is being developed in task 4.3 "Large Area Detector" for optimized operation in vacuum. Reduced constraints on the pressure vessel, and lower gamma sensitivity, can potentially be achieved by operating the detector at lower gas pressure, typically between 50 mbar and 100 mbar. This low-pressure mode remained to be studied. Additionally, the size of the RAMSES grids has been enlarged by a factor of 3 to achieve uniform response in each module, and the surface of neutron convertor per unit of solid angle has been increased by 50% to increase the detection efficiency. The following figure shows a section of one RAMSES module (drawing on the left) with 2 columns of grids with no dead zone between them. The photo on the right shows a grid column waiting for its mounting in the RAMSES prototype.

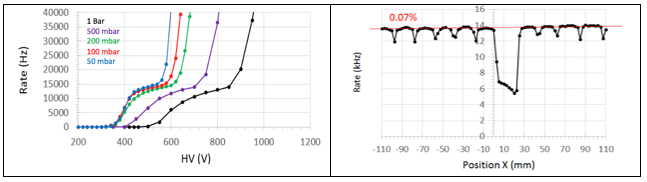

Our first objective was to study the operation of a MultiGrid detector flushed with 50 mbar of Ar-CO2 with minim gas flow. Since the RAMSES prototype wasn't available yet for testing, we did our measurements with the prototypes developed during the CRISP project. The results show that, compared to 1 bar, the detector performs better at 50 mbar, with improved dead time, gamma sensitivity, and operating voltage. The figure bellow shows (on the left) the "counting versus HV" curves at different pressures from 1 bar to 50 mbar: The best "counting plateaus" are obtained between 50 mbar and 200 mbar. On the right, one can see a scan of the detector with a collimated beam. The small jumps correspond to the gap between the grids. The large jump in the middle corresponds to a grid with a Boron film different from the other grids.

The pressure inside the TOF chamber might change without notice; in such cases, an automatic system must 1) open a valve between the detector vessel and the TOF chamber, and 2) switch off power supplies. We are developing such a system for the RAMSES prototype.

A new signal processing, which we call "weighted First Active Channel" is in development for improved position measurement. Preliminary results indicate that the gain in spatial resolution will be close to 2 compared to our standard signal processing (selection of the first active channel).

Stability measurements during several days were performed with a prototype exposed to a neutron flux of 500 kHz. These measurements give crucial information on the selection of the gas flow and internal materials.

In conclusion, very promising results, and important information, have been obtained with several MultiGrid prototypes studied in the low-pressure mode. This mode is validated. The plan for the next period is to test the RAMSES prototype on a real TOF instrument with a pressure control automatic system.

Two postdoc, V. Buridon, and Fabien Lafont, are working full time on the project with the support of many ILL staff members from different services (Detector, Mechanics, Electronics). Fabien Lafont on the left, and Victor Buridon on the right, are smiling shortly after the IN6 prototype, equipped with the new grids, started to produce first results.

is funded by the European Union Framework Programme for Research and Innovation Horizon 2020, under grant agreement 676548.

is funded by the European Union Framework Programme for Research and Innovation Horizon 2020, under grant agreement 676548.