Integrated Control System (ICS)

The Integrated Control System (ICS) for the European Spallation Source is a complex network of hardware, software and configuration databases that integrates the operations of all facility infrastructures. It is based on the Experimental Physics and Industrial Constrol System (EPICS) framework. The control system at ESS is essential for the synchronisation and day-to-day running of all the equipment responsible for the production of neutrons for the experimental programs.

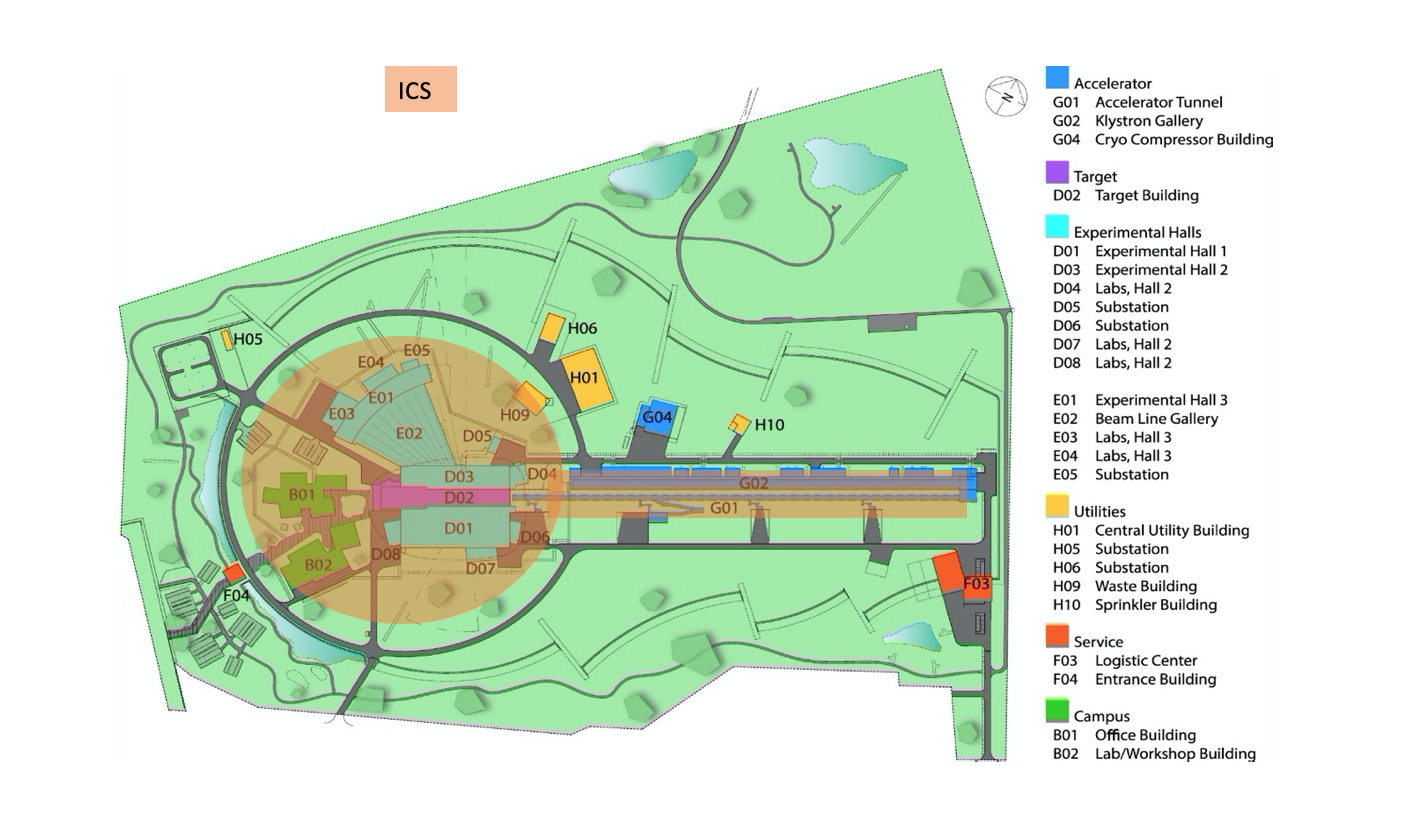

It is a distributed system that is organised in multiple layers. The top layer represents the human machine interfaces and high-level applications that connect to the Control Box, the middle layer, running the EPICS control system framework, and to additional services such as the Timing, Machine Protection and archival systems. The ICS will control the large and complex conventional facilities, including the control for the accelerator, target, neutron scattering systems.

Current

- System design and architecture is completed. Test systems are running and commissioning is ongoing.

- Delivery from In-kind Partners is in good progress and there is good interaction with the 9 In-kind Partners.

- There is an established collaboration framework with DESY, Big Science Sweden, MAX IV, ITER and others for the exchange of experience and requirements.

- Very active in communities and conferences of control system development and implementation from large scale facilities.

- ESS is contributing to the EPICS community and the open source development of the EPICS 7 software. The current chair of the EPICS Council is from ESS.

Future

- Analyze how the ICS elements can best be prepared for the use of Artificial Intelligence (AI) and Machine Learning.

- The aim is to augment ICS with machine learning technology that can continue to evolve as technology becomes available.

- During the commissioning of equipment and systems, data will be collected with the aim to lower operation, maintenance and spare part costs as much as possible.

- The three focus areas of technical advances, machine protection and large-scale integration will remain a priority and dedicated effort will be allocated to this.